Humanity has sought cleaner, more sustainable ways to power our lives for generations. Today, hydrogen emerges as a frontrunner in this quest, offering a versatile and planet-friendly fuel source.

But how do we unlock its potential?

Enter hydrogen electrolyzers, the unsung heroes of the clean energy revolution.

At Hydrogenera, we believe in the transformative power of hydrogen. We're dedicated to developing cutting-edge electrolyzer technology that makes hydrogen production efficient, accessible, and sustainable.

But before we delve into the specifics, let's dive deeper into the world of hydrogen electrolyzers and understand their critical role in the hydrogen ecosystem.

But how do we unlock its potential?

Enter hydrogen electrolyzers, the unsung heroes of the clean energy revolution.

At Hydrogenera, we believe in the transformative power of hydrogen. We're dedicated to developing cutting-edge electrolyzer technology that makes hydrogen production efficient, accessible, and sustainable.

But before we delve into the specifics, let's dive deeper into the world of hydrogen electrolyzers and understand their critical role in the hydrogen ecosystem.

Understanding the Electrolysis process

Step 1: The Ingredients:

Step 2: Electrolyzer Setup:

Think of the electrolyzer as a container with two electrodes (positive and negative) immersed in water.

Step 3: Electricity Takes Charge:

Electricity flows through the water when we connect the electrolyzer to a power source.

Step 4: The Splitting Act:

The magic happens here. The electricity energises the water molecules, causing them to split apart.

Step 5: Hydrogen Freedom:

Hydrogen (H) atoms gather at the negative electrode, forming free hydrogen gas (H2). This is our clean fuel!

Step 6: Oxygen Release:

Meanwhile, oxygen (O) atoms combine at the positive electrode, forming oxygen gas (O2) that is released harmlessly into the air.

Step 7: Clean Hydrogen Fuel:

That's it! We've used electricity to split water molecules, producing clean hydrogen fuel and releasing only oxygen gas.

- Water: Our starting point is the abundant and familiar H2O molecule.

- Electricity: Clean electricity from renewable sources like solar or wind powers the process.

- Electrolyzer: The specialised machine that performs the transformation.

Step 2: Electrolyzer Setup:

Think of the electrolyzer as a container with two electrodes (positive and negative) immersed in water.

Step 3: Electricity Takes Charge:

Electricity flows through the water when we connect the electrolyzer to a power source.

Step 4: The Splitting Act:

The magic happens here. The electricity energises the water molecules, causing them to split apart.

Step 5: Hydrogen Freedom:

Hydrogen (H) atoms gather at the negative electrode, forming free hydrogen gas (H2). This is our clean fuel!

Step 6: Oxygen Release:

Meanwhile, oxygen (O) atoms combine at the positive electrode, forming oxygen gas (O2) that is released harmlessly into the air.

Step 7: Clean Hydrogen Fuel:

That's it! We've used electricity to split water molecules, producing clean hydrogen fuel and releasing only oxygen gas.

What are Hydrogen Electrolyzers?

Imagine a machine that splits water (H2O) into its essential components, hydrogen (H2) and oxygen (O2), using electricity.

That's what a hydrogen electrolyzer does.

By applying electrical energy, the electrolyzer breaks the chemical bonds of water molecules, liberating clean, green hydrogen fuel.

This process involves passing an electric current through water, typically using electrodes of precious metals such as platinum or less expensive alternatives like nickel or stainless steel.

There are three main types of electrolyzers: alkaline electrolysers, proton exchange membrane (PEM) electrolysers, and solid oxide electrolysers.

Each type has its unique characteristics, advantages, and applications.

That's what a hydrogen electrolyzer does.

By applying electrical energy, the electrolyzer breaks the chemical bonds of water molecules, liberating clean, green hydrogen fuel.

This process involves passing an electric current through water, typically using electrodes of precious metals such as platinum or less expensive alternatives like nickel or stainless steel.

There are three main types of electrolyzers: alkaline electrolysers, proton exchange membrane (PEM) electrolysers, and solid oxide electrolysers.

Each type has its unique characteristics, advantages, and applications.

1. Alkaline Electrolyzers

Alkaline electrolysers have been the most extended and mature technology among the three types.

They operate by immersing electrodes in an alkaline electrolyte solution, usually potassium hydroxide (KOH) or sodium hydroxide (NaOH).

Alkaline electrolysers are known for their reliability, efficiency, and relatively low capital costs. They are famous for large-scale industrial applications, such as hydrogen production for ammonia synthesis or refining.

This is the electrolyser technology we use in Hydrogenera.

Alkaline electrolysers have been the most extended and mature technology among the three types.

They operate by immersing electrodes in an alkaline electrolyte solution, usually potassium hydroxide (KOH) or sodium hydroxide (NaOH).

Alkaline electrolysers are known for their reliability, efficiency, and relatively low capital costs. They are famous for large-scale industrial applications, such as hydrogen production for ammonia synthesis or refining.

This is the electrolyser technology we use in Hydrogenera.

2. Proton Exchange Membrane (PEM) Electrolyzers

PEM electrolysers have gained traction due to their ability to operate efficiently at low temperatures and pressures.

These electrolysers use a solid polymer electrolyte membrane, typically made of materials like Nafion, to conduct protons while blocking the passage of gases.

This enables PEM electrolysers to produce high-purity hydrogen suitable for fuel cells or transportation applications.

Their compact size and rapid response to changes in electricity input make them ideal for distributed hydrogen production and renewable energy integration.

PEM electrolysers have gained traction due to their ability to operate efficiently at low temperatures and pressures.

These electrolysers use a solid polymer electrolyte membrane, typically made of materials like Nafion, to conduct protons while blocking the passage of gases.

This enables PEM electrolysers to produce high-purity hydrogen suitable for fuel cells or transportation applications.

Their compact size and rapid response to changes in electricity input make them ideal for distributed hydrogen production and renewable energy integration.

3. Solid Oxide Electrolyzers

Solid oxide electrolysers (SOEs) operate at high temperatures, typically above 500°C, and utilise a solid ceramic electrolyte, such as yttria-stabilized zirconia (YSZ).

SOEs offer high efficiency and are capable of directly converting carbon dioxide (CO2) into carbon monoxide (CO) or syngas (a mixture of hydrogen and carbon monoxide) through a process known as co-electrolysis, offering a potential pathway for carbon-neutral or even carbon-negative hydrogen production.

Solid oxide electrolysers (SOEs) operate at high temperatures, typically above 500°C, and utilise a solid ceramic electrolyte, such as yttria-stabilized zirconia (YSZ).

SOEs offer high efficiency and are capable of directly converting carbon dioxide (CO2) into carbon monoxide (CO) or syngas (a mixture of hydrogen and carbon monoxide) through a process known as co-electrolysis, offering a potential pathway for carbon-neutral or even carbon-negative hydrogen production.

Optimising Electrolyser Efficiency

While electrolysers offer a revolutionary step towards a green future, their effectiveness hinges on maximising efficiency. Like any other machine, various factors influence how much clean hydrogen an electrolyser can produce from a given amount of electricity.

Understanding these factors is crucial for continuous improvement and unlocking the full potential of this technology.

Hydrogenera has pushed the boundaries of electrolyser technology through continuous research and development. Our proprietary design and material advancements have improved electrolysis efficiency surpassing 85%.

This superior efficiency translates to higher hydrogen production per unit of electricity, ultimately reducing costs and making green hydrogen even more competitive.

Understanding these factors is crucial for continuous improvement and unlocking the full potential of this technology.

- Electrolyte Properties: The type and concentration of the electrolyte solution significantly impact efficiency. Factors like conductivity, purity, and operating temperature play a role.

- Electrode Materials: The materials used for the electrodes influence the rate of electrochemical reactions and energy losses. Selecting the right combination is crucial for optimal performance.

- Operating Conditions: Temperature, pressure, and current density all influence the efficiency of the electrolysis process. Finding the optimal balance is critical.

- Stack Design: The internal configuration of the electrolyser, including membrane thickness and electrode spacing, can affect efficiency by minimising energy losses within the system.

Hydrogenera has pushed the boundaries of electrolyser technology through continuous research and development. Our proprietary design and material advancements have improved electrolysis efficiency surpassing 85%.

This superior efficiency translates to higher hydrogen production per unit of electricity, ultimately reducing costs and making green hydrogen even more competitive.

Why are Electrolysers Important?

Electrolysers are the cornerstone of a hydrogen-powered future. They enable clean hydrogen production from renewable energy sources like solar, wind, or geothermal power.

This green hydrogen, produced without any harmful emissions, holds immense potential to revolutionise numerous sectors:

1. Transportation Unleashed: Emissions-free Mobility Takes Off:

Say goodbye to tailpipe exhaust! Hydrogen-powered vehicles, from cars and buses to trucks and airplanes, are becoming a reality.

Electrolysers pave the way for clean transportation by generating hydrogen fuel that powers these vehicles with zero emissions.

Imagine zipping through your city in a hydrogen-powered car, leaving only clean air in your wake.

2. Energy on Demand: Powering Homes and Industries Sustainably:

Electrolysers can also store renewable energy in hydrogen, acting as a giant green battery. This stored hydrogen can generate clean electricity during peak demand periods or when renewable sources are unavailable.

This means a more reliable and sustainable energy grid that powers our homes, businesses, and industries with minimal environmental impact.

3. Industrial Decarbonization

Many industries, like steel production and chemical refineries, rely heavily on fossil fuels, contributing significantly to greenhouse gas emissions.

But electrolysers offer a game-changer.

These industries can decarbonise their processes by using green hydrogen generated from renewable sources, significantly reducing their environmental footprint.

4. Beyond the Obvious: Hydrogen's Diverse Applications:

The potential of hydrogen goes far beyond these core examples.

It can heat buildings, fuel ships, and power portable generators.

As electrolyser technology improves and becomes more cost-effective, we expect a surge in innovative applications across various sectors.

At Hydrogenera, we understand the pivotal role of electrolysers in unleashing hydrogen's vast potential as a clean and adaptable energy solution.

Having already executed successful projects in Poland, Turkey, and Bulgaria, we're proud to lead electrolyser technology.

Our expertise extends across various industries, and we're excited to announce that more projects are on the horizon, spanning sectors such as transportation, energy storage, and industrial decarbonisation.

This green hydrogen, produced without any harmful emissions, holds immense potential to revolutionise numerous sectors:

1. Transportation Unleashed: Emissions-free Mobility Takes Off:

Say goodbye to tailpipe exhaust! Hydrogen-powered vehicles, from cars and buses to trucks and airplanes, are becoming a reality.

Electrolysers pave the way for clean transportation by generating hydrogen fuel that powers these vehicles with zero emissions.

Imagine zipping through your city in a hydrogen-powered car, leaving only clean air in your wake.

2. Energy on Demand: Powering Homes and Industries Sustainably:

Electrolysers can also store renewable energy in hydrogen, acting as a giant green battery. This stored hydrogen can generate clean electricity during peak demand periods or when renewable sources are unavailable.

This means a more reliable and sustainable energy grid that powers our homes, businesses, and industries with minimal environmental impact.

3. Industrial Decarbonization

Many industries, like steel production and chemical refineries, rely heavily on fossil fuels, contributing significantly to greenhouse gas emissions.

But electrolysers offer a game-changer.

These industries can decarbonise their processes by using green hydrogen generated from renewable sources, significantly reducing their environmental footprint.

4. Beyond the Obvious: Hydrogen's Diverse Applications:

The potential of hydrogen goes far beyond these core examples.

It can heat buildings, fuel ships, and power portable generators.

As electrolyser technology improves and becomes more cost-effective, we expect a surge in innovative applications across various sectors.

At Hydrogenera, we understand the pivotal role of electrolysers in unleashing hydrogen's vast potential as a clean and adaptable energy solution.

Having already executed successful projects in Poland, Turkey, and Bulgaria, we're proud to lead electrolyser technology.

Our expertise extends across various industries, and we're excited to announce that more projects are on the horizon, spanning sectors such as transportation, energy storage, and industrial decarbonisation.

Electrolyser’s Safety and Maintenance

As hydrogen emerges as a critical player in the clean energy transition, misconceptions and concerns around its safety linger.

Unlike gasoline, hydrogen is lighter than air, readily dispersing upon release, minimising the risk of accidents.

Additionally, it's non-toxic, reducing environmental and health hazards.

Stringent regulations govern every stage of the hydrogen value chain, from production and storage to transportation and usage.

International standards and regional guidelines ensure responsible management and ongoing research continuously refines safety protocols.

Unlike gasoline, hydrogen is lighter than air, readily dispersing upon release, minimising the risk of accidents.

Additionally, it's non-toxic, reducing environmental and health hazards.

Stringent regulations govern every stage of the hydrogen value chain, from production and storage to transportation and usage.

International standards and regional guidelines ensure responsible management and ongoing research continuously refines safety protocols.

Hydrogenera's Commitment to Safety:

Beyond industry standards, Hydrogenera prioritises safety throughout its operations:

We design and assemble over 90% of the components, including the control systems, required for each electrolyser in-house, ensuring meticulous attention to detail and quality control.

The remaining 10% undergoes rigorous testing procedures to uphold the highest standards for our products.

Beyond industry standards, Hydrogenera prioritises safety throughout its operations:

- Design for Safety: Electrolysers incorporate robust materials, leak detection systems, and automatic shut-off mechanisms.

- Rigorous Testing: Every unit undergoes thorough testing to ensure compliance with international safety regulations.

- Comprehensive Training: Hydrogenera equips operators and maintenance personnel with essential safety knowledge and practices.

We design and assemble over 90% of the components, including the control systems, required for each electrolyser in-house, ensuring meticulous attention to detail and quality control.

The remaining 10% undergoes rigorous testing procedures to uphold the highest standards for our products.

Hydrogenera's Electrolysers Drive Efficiency and Innovation:

At Hydrogenera, we're constantly pushing the boundaries of electrolyser technology. We're committed to the following:

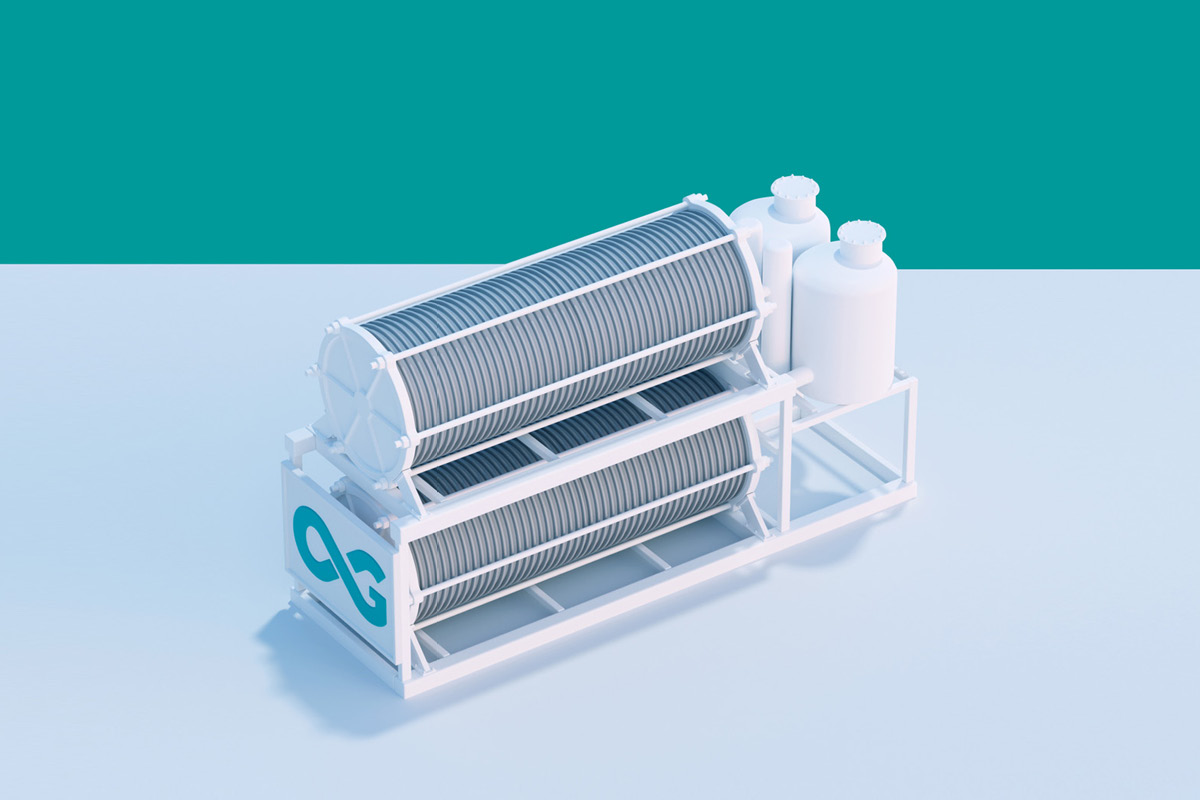

The Hydrogenera Electrolyser AEM Z revolutionises the way we produce hydrogen.

- Improving efficiency: Developing innovative designs and control systems to maximise hydrogen production per unit of energy input.

- Reducing costs: Making electrolysers more affordable to accelerate widespread adoption.

- Scaling production: Meeting the growing demand for clean hydrogen with robust manufacturing capabilities.

The Hydrogenera Electrolyser AEM Z revolutionises the way we produce hydrogen.

- Advanced Hydrogen Technology

- Electrolysis efficiency > 85% reduces the need for additional cooling

- Custom electronic control, built in-house, without pre-made solutions

- Modular allows easy upscaling with no limitation on the maximum intake of electricity

- Minimum maintenance for enhanced reliability

- Built for future expansion to adapt to growing energy demands

- Producing hydrogen with purity up to 99.999%

- Minimum maintenance for enhanced reliability Hydrogenera's technology enables us to deliver customised indoor solutions for any application, configuration and size!

Powering your business with Hydrogen

The potential of hydrogen is undeniable. With advancements in electrolyser technology, we're on the cusp of unlocking a clean energy future powered by hydrogen.

At Hydrogenera, we're proud to be at the forefront of this revolution, and we invite you to join us on this exciting journey.

Contact us to learn more about our innovative electrolyser solutions and how we can help you build a hydrogen energy strategy for your business.

At Hydrogenera, we're proud to be at the forefront of this revolution, and we invite you to join us on this exciting journey.

Contact us to learn more about our innovative electrolyser solutions and how we can help you build a hydrogen energy strategy for your business.